Engineering researchers from the Department of Energy’s (DoE) Argonne National Laboratory are set to use social media AI techniques to better optimize the geometries of 3D printed parts.

Mark Messner, a principal mechanical engineer at Argonne, is among those who initially developed the novel approach back in 2019, claiming it was a better way to predict how materials might behave under extreme temperatures and pressures. While current simulation-based prediction methods work as intended, they often require supercomputer-level processing power (and a lot of patience) to accurately predict how a geometry may behave under certain conditions.

“You would typically have to run tons of physics-based simulations to solve that problem,” said Messner.

This is especially true if researchers already have a specific set of properties in mind, such as stiffness, density, and strength, and want to determine the optimized part structure they would need to yield those properties. Intended as an alternative, the Argonne method is reportedly more than 2000x faster than modern day part performance simulations, and is capable of running on a regular laptop with a consumer GPU.

How does social media play a part?

Messner’s work can be traced back to his time as a postdoctoral researcher at Lawrence Livermore National Laboratory, where he and his team were trying to 3D print complex micron-scale structures. The team’s progress was reportedly slow, so they looked to AI to see if they could expedite their research.

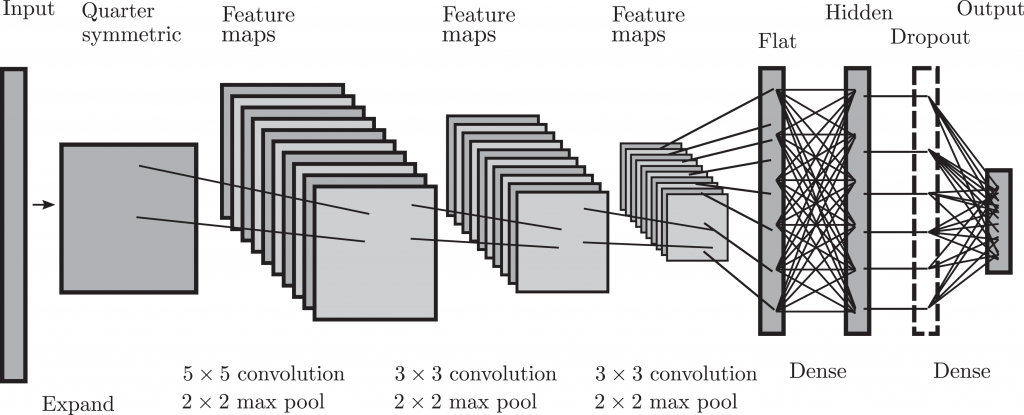

At the time, the budding social media titans of Silicon Valley had begun using convolutional neural networks, a type of AI that finds patterns in large sets of data, for facial and object recognition purposes in images. Messner believed he could apply this concept to the 3D realm.

“My idea was that a material’s structure is no different than a 3D image,” he explains. “It makes sense that the 3D version of this neural network will do a good job of recognizing the structure’s properties — just like a neural network learns that an image is a cat or something else.”

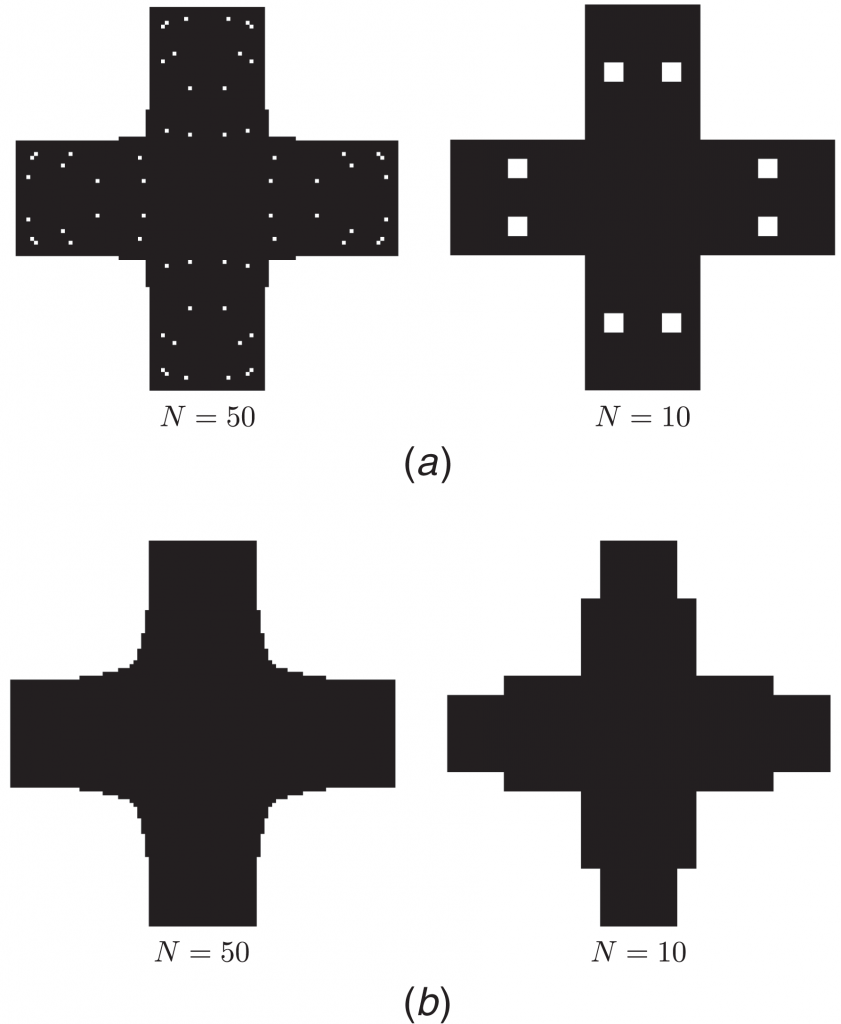

To see if his idea would work, Messner designed a defined 3D geometry and used conventional physics-based simulations to create a set of two million data points. Each of the data points linked his geometry to ‘desired’ values of density and stiffness. Then, he fed the data points into a neural network and trained it to look for the desired properties.

Finally, Messner used a genetic algorithm – an iterative, optimization-based class of AI – together with the trained neural network to determine the structure that would result in the properties he sought. Impressively, his AI approach found the correct structure 2,760x faster than the conventional physics simulation.

AI, 3D printing, and the nuclear sector

One of the most promising applications of the AI method is in 3D printing. Since the approach tends to come up with extremely complicated geometries, conventional manufacturing processes would struggle to actually produce the structures suggested by the model. The additive nature of 3D printing makes it possible to fabricate these optimized structures, regardless of the intricacies of the geometry, enabling scientists to achieve the properties they are seeking.

Messner believes the ‘future of mechanical engineering’ may very well be a combination of AI and additive manufacturing: “You would give the structure — determined by a neural network — to someone with a 3D printer and they would print it off with the properties you want. We are not quite there yet, but that’s the hope.”

A more immediate application of the technology is in the nuclear industry, for material design purposes. In fact, Messner’s team is currently working with nuclear startup Kairos Power to design a molten salt nuclear reactor core using AI. The Argonne model will eventually help the Kairos team predict how stainless steel 316H might handle the high temperatures and pressures inherent to a nuclear reactor core over a number of decades.

“This is a small, but vital, part of the work we are doing for Kairos Power,” concludes Rui Hu, a nuclear engineer at Argonne. “Kairos Power wants very accurate models of how reactor components are going to behave inside its reactor to support its licensing application to the Nuclear Regulatory Commission. We look forward to providing those models.”

AI and machine learning have undoubtedly made their way into 3D printing, with applications in everything from materials design to defect detection. Earlier this month, researchers from Charles University’s Computer Graphics Group (CGG) developed a ML-based technique that could help unlock higher fidelity color 3D printing. By simulating the 3D printing process, the team was able to train an algorithm to find the optimal build parameters for limiting color bleeding, and improving part accuracy.

Elsewhere, at Argonne and Texas A&M University, scientists have previously developed a novel ML approach to defect detection in 3D printed parts. Using real-time temperature data, together with ML algorithms, the scientists were able to make correlative links between thermal history and the formation of subsurface defects.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Argonne National Laboratory, Argonne, Illinois, USA. Photo via DoE.