Argonne advanced fuel injector research sheds new light on cavitation

Fuel injector spray holes are barely the width of human hair but these small components play a powerful role in making engines more efficient and cleaner burning. The formation of vapor-filled cavities, a phenomenon known as cavitation, threatens injector performance by leading to nozzle damage and can even impact engine performance by driving up exhaust emissions.

A complete understanding of how cavitation occurs has been elusive, leaving manufacturers to try to design and optimize cavitation-suppressing injectors using slow and expensive methods of trial and error. Creating fuel injectors of the future, the kind that can deliver increasingly high pressures, demands more insight.

The U.S. Department of Energy’s Argonne National Laboratory is providing this much needed knowledge. Using X-ray scanning and imaging techniques, Argonne researchers have tracked how cavities form inside a diesel fuel injector and quantified their impact on fuel distribution outside the injector. The work is a recent highlight reported by the U.S. Driving Research and Innovation for Vehicle efficiency and Energy Sustainability (U.S. DRIVE), a government-industry partnership focused on advanced automotive and energy-related infrastructure technology.

The process

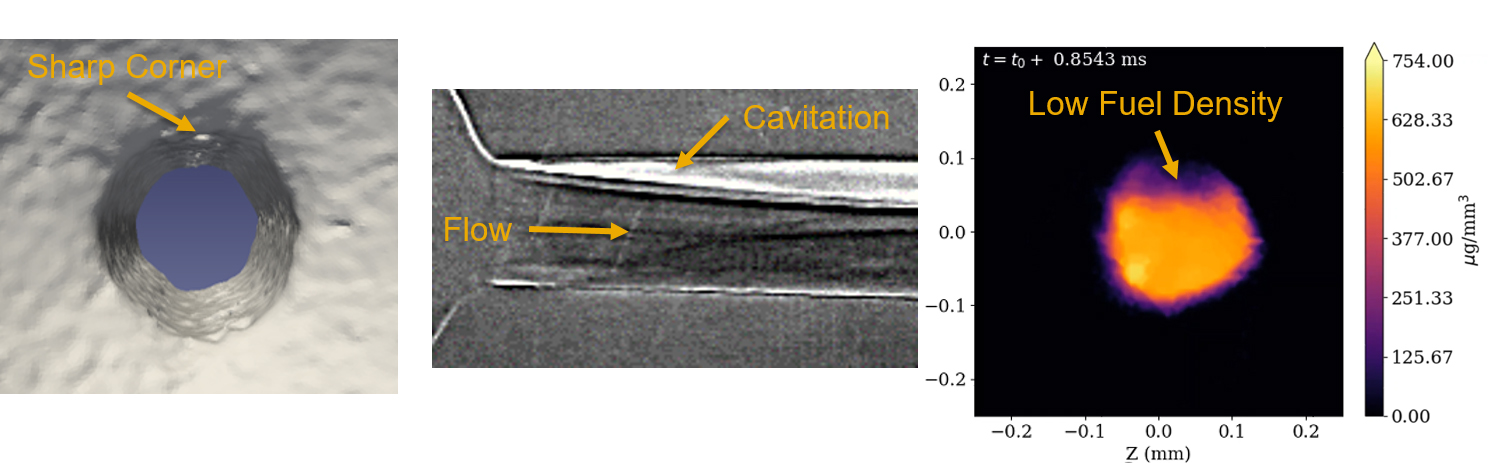

Researchers began by measuring the geometry of a fuel injector by performing X-ray tomography, a scanning technique, at the Advanced Photon Source at Argonne, the world’s brightest X-ray light source in the Western Hemisphere.

“X-ray tomography has been around for a long time, it’s used in medical applications every day,” said Chris Powell, an Argonne engine research scientist. The APS, however, produces X-rays a billion times brighter than those in a typical dentist office.

“The APS gives us superior optical quality because the X-rays all travel in the same direction and are very well defined in space, Powell said. “This allows us to take measurements with more accuracy than with other X-ray sources.”

Next, researchers used high-speed X-ray imaging to observe what happened when fuel passed through the injector. They observed that as fuel passed over the sharp corner, a low-pressure region formed, causing the fuel to vaporize, in a process known as cavitation.

Lastly, researchers performed time-resolved X-ray tomography of the spray to quantify the fuel that emerged from the nozzle. Their measurements revealed that cavitation inside the fuel injector nozzle generated a highly asymmetric fuel spray, changing the mixing of fuel and air that is all-important for clean, efficient combustion.

The impact

Together, these insights in fuel injector research provide a more complete picture of how cavities form and affect flow through an injector as well as the external fuel distribution, Powell said.

“With this new diagnostic tools, we can build cavitation models and advance the design of injectors capable of higher pressures and improved performance, improving efficiency and reducing emissions over the lifetime of the engine,” he said.

This work was conducted in association with the U.S. Driving Research and Innovation for Vehicle efficiency and Energy sustainability (U.S. DRIVE) partnership. It is funded by the Vehicle Technologies Office within DOE’s Office of Energy Efficiency and Renewable Energy.