Pressure Drop Experimental Loop for Investigations of Core Assemblies in Advanced Nuclear Reactors (PELICAN)

PELICAN, the Pressure Drop Experimental Loop for Investigations of Core Assemblies in Advanced Nuclear Reactors, is a novel experimental facility designed and constructed at Argonne National Laboratory to recreate the hydraulic flow conditions for the Versatile Test Reactor (VTR) currently under development by the U.S. Department of Energy.

The VTR will rely on fast neutrons to enable new and wide-ranging experiments to support development of the various advanced reactor technologies. With the high flux achievable, accelerated testing of fuel and materials will be made possible. To support VTR design efforts, PELICAN is used to replicate VTR’s primary heat transport system (PHTS) and the measurement objectives for data generated from this test facility are driven primarily by the validation needs for code calculations and simulations of the reference VTR core. These objectives focus on the need to validate pressure drop results across the various segments of the fuel assembly, including the axial reflectors, fuel, and transition regions, as they relate directly to the pumping power and safety behavior of the reactor. Critical to accurately representing the physical flow fields is empirical knowledge of Reynolds number (Re) and pressure drop (ΔP). Furthermore, the conditions and thermohydraulic state of the flowing coolant must be known to ensure that material properties can be accurately captured by computational models.

Collectively, these parameters can be obtained by the current suite of sensors within the PELICAN loop, which include the use of a volumetric flow meter, thermocouples, and pressure transmitters. These have been selected to provide measurements of pertinent thermal and hydraulic properties across the range of conditions planned for the various testing activities. These sensors are able to accurately measure the physical flow fields in a fashion that is non-invasive and does not influence the normal flow behavior.

Milestones

Winter 2020-2021

An initial testing campaign and subsequent report focused on the commissioning of the new device, facility characterization that assesses the operational capabilities of the control and acquisition systems, and the first phase of experimental testing. During this first phase of testing, various orifice plates were used as simple test articles for which a known and measurable pressure drop can be generated as a function of flowrate. Using these orifice plates first provided both a means of validating the experimental facility and a simple geometry from which comparative flow simulations can be performed.

Spring 2021

Beginning in March 2021, the experimental testing phase shifted from orifice plates to two iterations of upper reflector designed, fabricated, and tested for VTR. One design features sharp edges while the other features smoothed edges and will provide insight into the role that local boundary conditions play on the fluid dynamics and resulting pressure drop.

Fall 2021

In preparation for the testing of the full VTR fuel assembly, the PELICAN facility was moved from the HiBay floor to a nearby subfloor area that facilitated the vertical expansion of the loop to accommodate the 342 cm long fuel assembly.

Winter 2021-2022

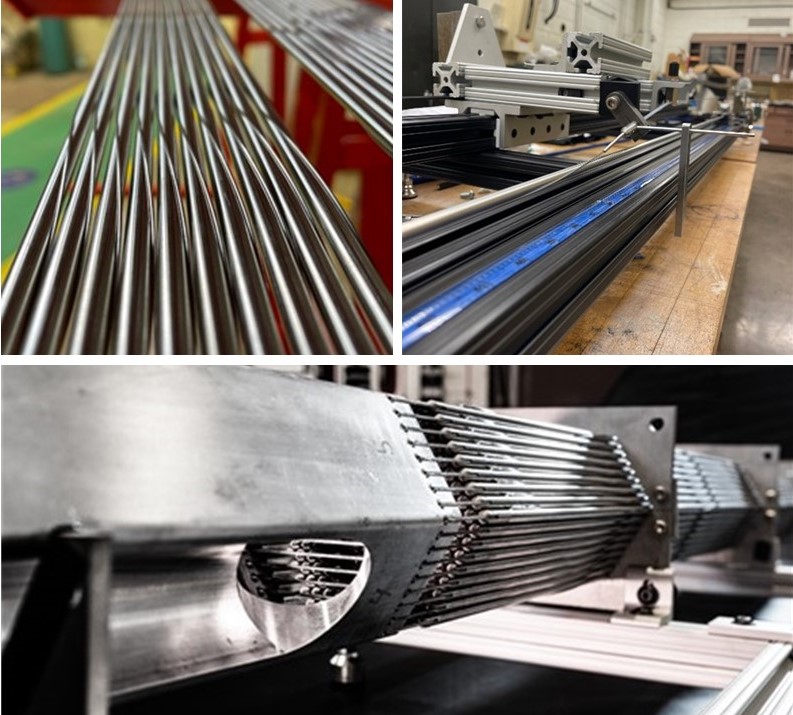

The most complex and time intensive feature of the full assembly was the fabrication of the pin bundle and its attachment to the lower reflector. New capabilities were established to allow for in-house fabrication of geometrically prototypic rod bundles of any length, diameter, and wire-wrapping pitch. The tool designed and built for this construction wrapped stainless steel wire at a helical pitch of 10.51-inch (26.6-cm) over the complete length of a 60-inch (1.52-m) stainless steel rod. The wire was fastened to the rod ends using first, resistance spot welding while in the tool, followed by a high frequency pulsed TIG weld for final securement. A total of 235 wire-wrapped pins were fabricated and 217 of these pins were chosen to form the final bundle that is attached via spacer plates to the lower reflector.

Spring 2022

Beginning in March 2022, experimental testing focused on gathering pressure drop across various sections and subsections of the fuel assembly at a variety of flow rates.

With the lower reflector and fuel pin bundle assembly fabrication complete, the complete fuel assembly comprised of inlet, lower reflector, fuel pin bundle, upper reflector, and outlet nozzle was installed within the full-length PELICAN loop.

A suite of tests were performed by sweeping differential pressure sensors across 16 pressure tap fittings welded to the duct wall. With these measurements the total pressure drop across the full prototypic VTR fuel assembly along the pressure drop across various subsections were gathered, analyzed and compared with analytical models, published data, and computational modeling. These results are presented in a final report.

Present

The PELICAN facility is pursuing collaborative funding opportunities with industrial partners. Its modular design and construction that uses off-the-shelf components allows the facility to be adapted to meet the needs and research goals for prospective sponsors.

PELICAN at a glance

- Loop Dimensions: 1.2 x 2.3 x 6.1 meters (4 x 7.5 x 20 feet)

- Test Section Cavity: up to 342 cm length, 11.1 cm side to side hexagon

- Operating Pressures: 2.7 bar, 40 psig

- Fluid Inventory: up to 133 liters (35 gallons)

- Operating Temperatures: < 120ºC

- Pump Power: 50 HP

- Operating Flow Rates: 0-54 kg/s, (0-850 GPM)

- Experimental Measurements: flow rates, point temperatures, static pressure, differential pressure