Rad/Nuc Incident Mitigation and Recovery Laboratories

The Rad/Nuc Incident Mitigation and Recovery Laboratory activities advance the capabilities of the U.S. government and our allies to increase the resiliency of the urban and rural environment against rad/nuc threat agents or accidental releases.

- Study the chemistry of radionuclides and their interaction with surfaces to understand their transport and fate in the urban environment.

- Develop selective CBRN separations techniques using solvent extraction, ion exchange, extraction chromatography, and functionalized nanomaterials.

- Develop novel methods of decontaminating surfaces to gross and final decontamination criteria.

- Develop methods of protecting and recovering critical infrastructure from rad/nuc contamination.

- Evaluate common equipment and recommend strategies and tactics for expediting a recovery decontamination operation.

- Develop surrogate radioactive fallout using various wet chemistry and high-temperature particle synthesis methods.

- Fabricate building material coupon standards for comparative testing and evaluation.

- Develop various computer models to; 1) predict the performance of miniature and full-scale separations systems including critical infrastructure; 2) design emergency systems to protect drinking water and waste water treatment plants; 3) help emergency responders develop objectives, strategies, and tactics for an efficient response; and 4) understand the timeline for deploying mitigation strategies.

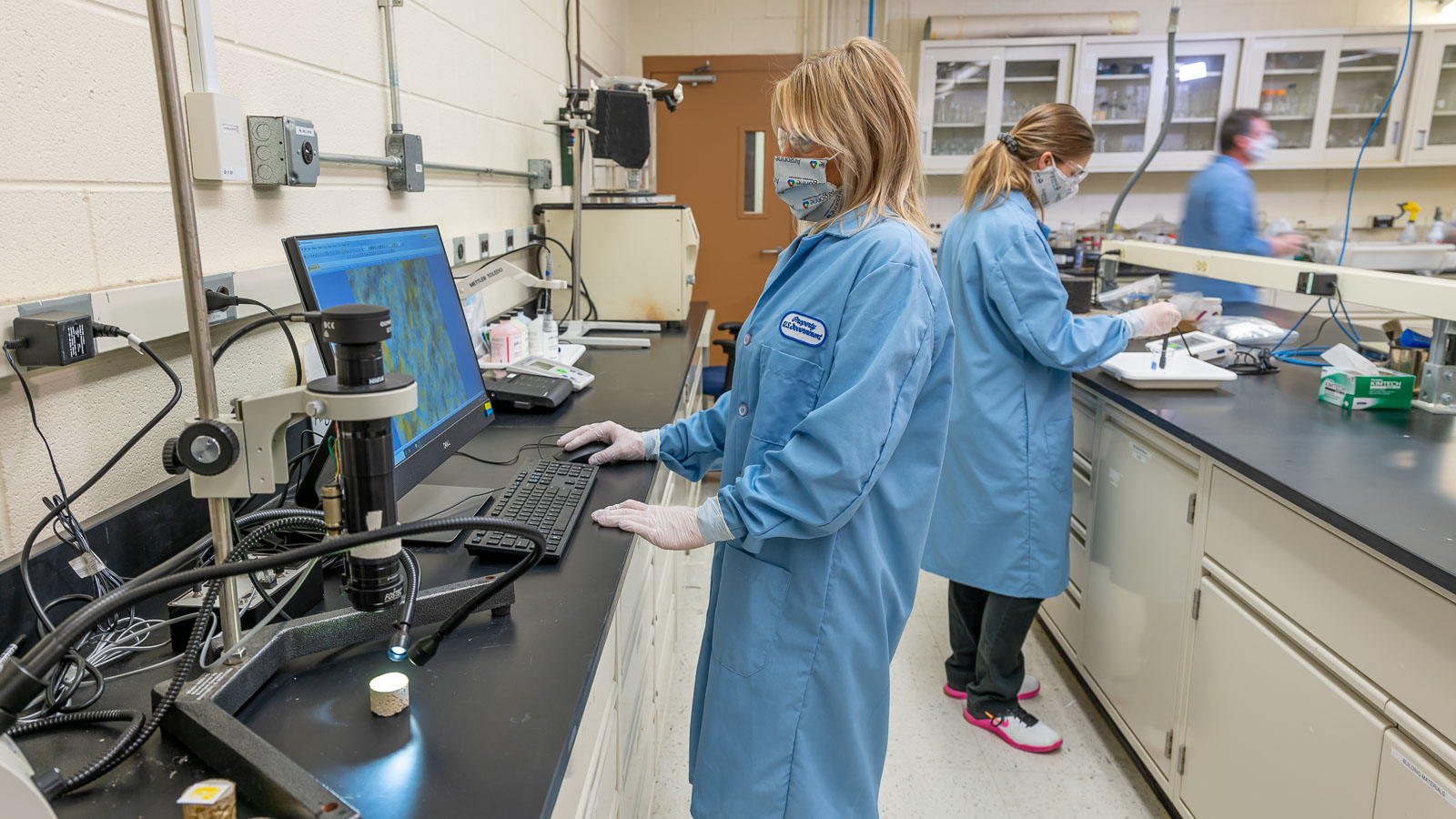

Instrumentation & Equipment

The Rad/Nuc Incident Mitigation and Recovery Laboratories are state-of-the-art laboratories for conducting radioactive and non-radioactive-based synthesis, characterization, and testing. It is fully equipped with inorganic and organic synthetic chemistry equipment and supplies and a suite of supporting equipment including: climate control cabinet, seven fume hoods and a vacuum frame hood for radioactive and non-radioactive testing, high temperature ovens, optical microscope, electrophoretic light scattering and surface potential measurement unit, viscometer, test columns, gamma/beta/alpha emitting radioactive tracers, fluorescent dyes, lyophilizer, Pistorius saw, He pycnometer, ultra-high speed mixers, ultrasonic baths, high-field permanent magnets and magnet test holders, magnetic test tube racks, and molds for fabricating concrete and asphalt samples of various sizes. It also houses equipment specific to nanosynthetic methods including a clean hood, glovebox, ultracentrifuge, dialysis membranes, and ultrahigh frequency sonication probes. Radioanalytical equipment includes a HPGe gamma detector, a NaI well-detector with automatic sample changer, and access to various alpha/beta counting systems. Unique equipment includes a high-temperature slag melter for producing melts and particulate off-gas, a test wall for large vertical sample decontamination testing, a high-pressure water decontamination test chamber, and a “hot” x-ray diffractometer. Our Lab has access to a “hot” scanning electron microscopy with energy dispersive x-ray analysis and a “hot” transmission electron microscope with electron diffraction analysis.