Device and Method for Fluidizing and Coating of Ultrafine Particles (ANL-IN-11-048)

- Device and Method for Fluidizing and Coating of Ultrafine Particles (ANL-IN-11-048)

The Invention

An ultra thin surface coating composed of metal oxides that, when applied to granular electrode materials on a large scale, promises to solve the structural instability of electrode materials and the resulting rapid fade of cell capacity at high voltages and high temperatures in lithium-ion batteries.

Argonne’s innovation, a powder nanocoating technology using metal oxides, has the following features:

- Gas-phase surface chemical reactions;

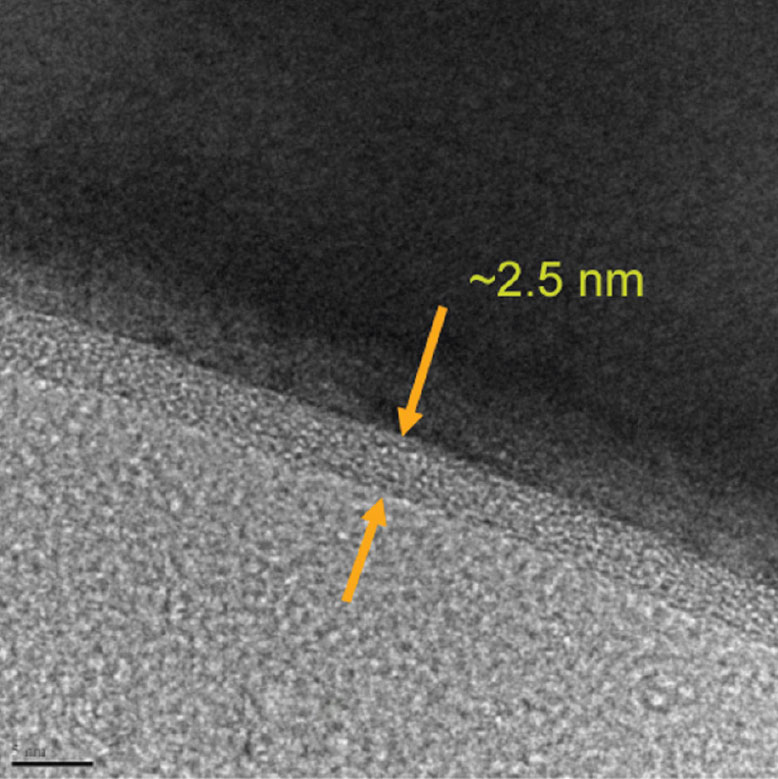

- A layer of extremely uniform metal oxide ultrathin film on granular cathode materials with precisely controlled surface morphology: smooth, conformal, and pin-hole free so that the electrode degradation reactions in the battery can be suppressed; and

- Film so ultra thin and precisely controlled in its thickness that the transfer of the charge across the electrode/electrolyte interface takes place with a very limited, or even a reduced, interface resistance.

In developing a surface coating for the electrodes of lithium-ion batteries, Argonne scientists sought to satisfy two requirements simultaneously:

- Create a uniform coating that will fully isolate electrodes from the electrolyte, and

- Create an ultra thin film that will allow the lithium ion and electron to easily tunnel without a large increase in impedance.

Conventional technologies have been unable to fulfill those requirements and have proved incapable of precisely controlling the coating film properties of film thickness and morphology. As a result, battery performance can be unstable.

Benefits

The new powder coating technology provides:

- Smooth fluidization of ultrafine powders via non-linear processing control;

- Online, real-time monitoring of powder fluidization status and surface chemical reaction;

- Well-controlled properties of the nanocoated film (conformity, thickness, and composition); and

- A novel process that is scalable, less energy-intensive, and at a lower cost.

Lithium-ion batteries made of these novel coated materials offer:

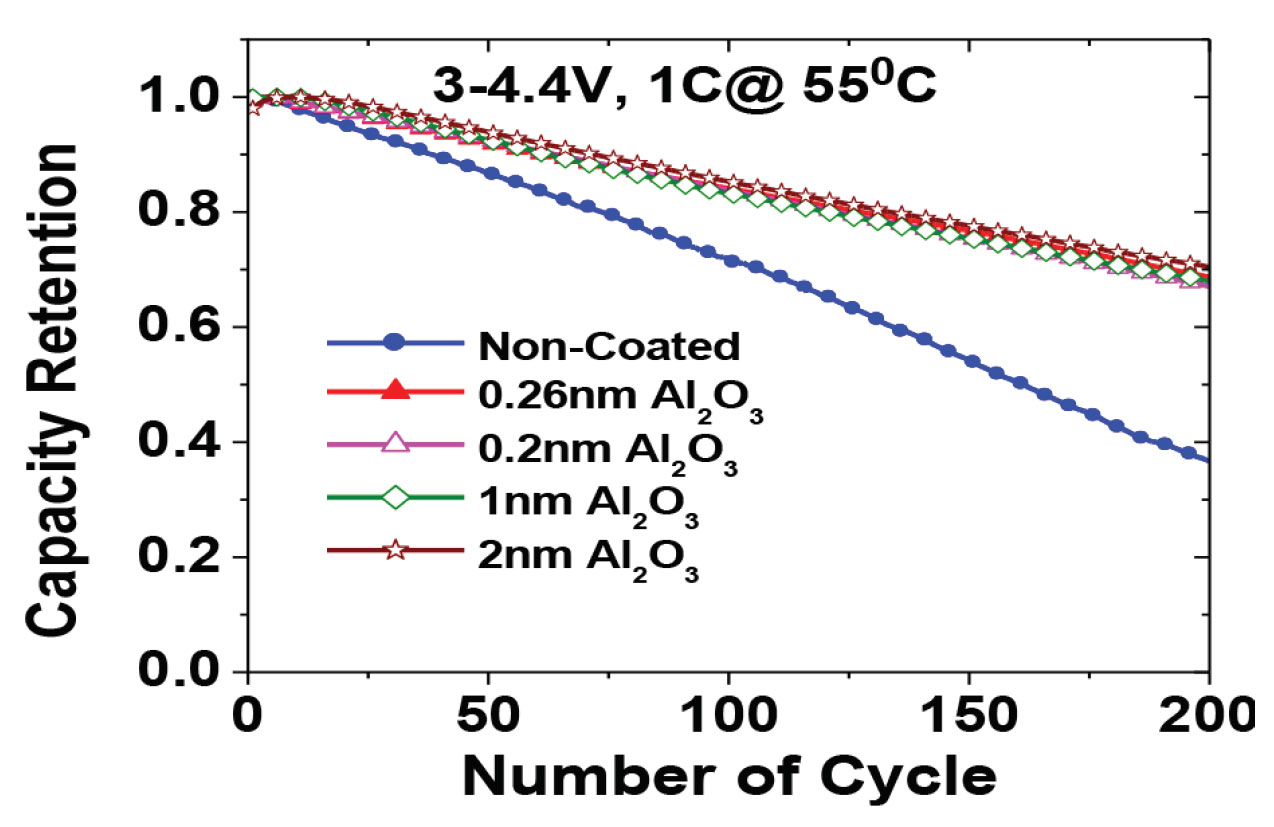

- Isolation of electrode from electrolyte, creating greater structural stability and effectively enhancing capacity retention;

- Greater stability;

- Longer lifespan;

- Higher energy/power densities;

- Greater safety; and

- Reduced cost and increased performance (figure 2) reliability.

Applications and Industries

- Hybrid electric vehicles

- Solar cells

- Ultracapacitors

- Cosmetics

Developmental Stage

Proof of concept. Lab scale has been demonstrated; small pilot scale up is on schedule.