Scientists from Argonne and Lawrence Berkeley national laboratories develop a new electrolyte that works as well in sub-zero conditions as room temperature

Range anxiety with electric vehicles rises as temperatures fall below freezing. In current lithium-ion batteries, the main problem is that the electrolyte is a liquid that begins to freeze at sub-zero temperatures. This condition severely limits the effectiveness of charging electric vehicles in cold regions and seasons.

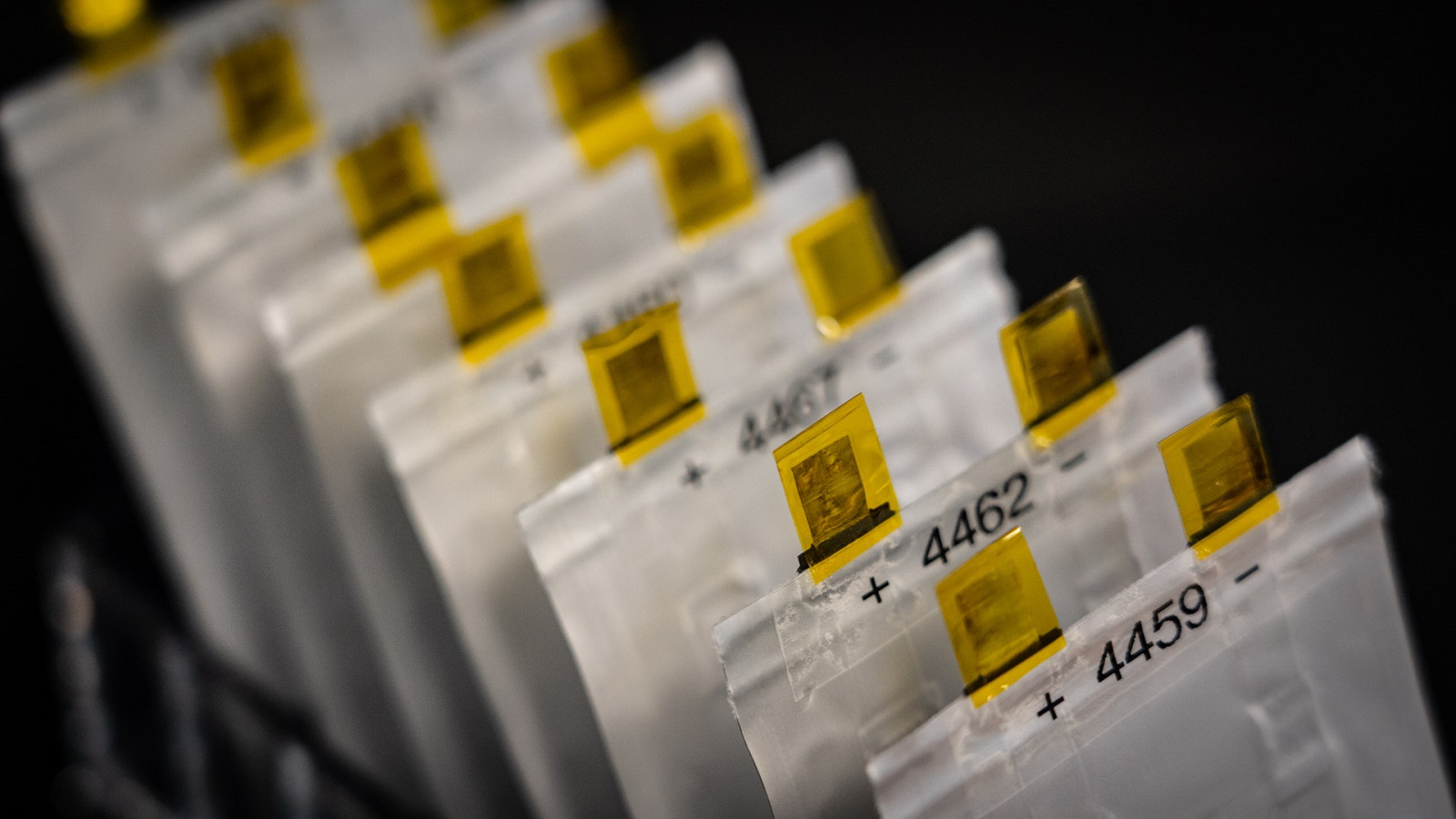

To address that problem, a team of scientists from the U.S. Department of Energy’s (DOE) Argonne and Lawrence Berkeley national laboratories developed a fluorine-containing electrolyte for sub-zero temperatures. In testing with laboratory cells, the team’s fluorinated electrolyte retained stable energy storage capacity for 400 charge-discharge cycles at minus 4 degrees Fahrenheit. Even at that sub-zero temperature, the capacity was equivalent to that of a cell with a conventional carbonate-based electrolyte at room temperature.

The team also determined at the atomic scale why their electrolyte composition worked so well. It depended on the position of the fluorine atoms within the molecules in the electrolyte transporting lithium ions and the number of those atoms.

The antifreeze electrolyte has a bonus property. It is much safer than the conventional electrolyte, since it will not catch fire.

California researchers use Advanced Photon Source to study antibody ‘cocktail’ that fights Lassa virus

Researchers at the La Jolla Institute for Immunology (LJI) used the bright X-ray beams produced by the Advanced Photon Source (APS), a DOE Office of Science user facility at Argonne to characterize three antibodies that target the protein structure of the Lassa virus, which is responsible for thousands of deaths annually in Africa. The antibodies were isolated from survivors of the disease.

The researchers strove to identify the virus’s weak spots, and they found that the most effective approach involved the use of a “cocktail” of the three antibodies to neutralize the virus. The antibody cocktail has been tested in nonhuman primates but is still awaiting federal approval for further study. In the meantime, the researchers were interested in more fully understanding how the antibodies worked.

To do so, they used a combination of cryo-electron microscopy (cryo-EM) technology provided by LJI and X-ray crystallography, with X-rays provided by the APS. Partial structures of the three different antibodies and interaction of the part of the virus’s protein structure with one of the antibodies were determined by X-ray crystallography. This information was used as initial model when fitting the cryo-EM maps.

Spinoff from Argonne-led innovation hub opens new frontier for batteries

Hayward-based startup company Blue Current has achieved success with an innovative battery material that was originally inspired by work done with the Joint Center for Energy Storage Research (JCESR), one of the DOE’s Energy Innovation Hubs. Led by DOE’s Argonne, JCESR brings together more than 150 researchers from 20 institutions — including national laboratories, universities and industry — to build materials to enable breakthrough batteries.

In 2015, a JCESR-sponsored laboratory at the DOE’s Berkeley Lab developed a breakthrough solid electrolyte called a “composite” that demonstrated strong performance. In batteries, electrolytes carry charge between the positive and negative electrodes. Recognizing the composite’s great potential, Blue Current developed it further.

Since then, the company has incorporated composite electrolytes into its solid-state battery cells. Solid-state batteries contain all solids and offer great potential to enhance the safety of batteries. Blue Current has refined its cells to the point that they are ready for large-scale manufacturing. Recently, an arm of Koch Industries has invested $30 million in the company to build its first large-scale factory in Hayward.

Argonne, UC Berkeley researchers discover ultrathin ferroelectricity

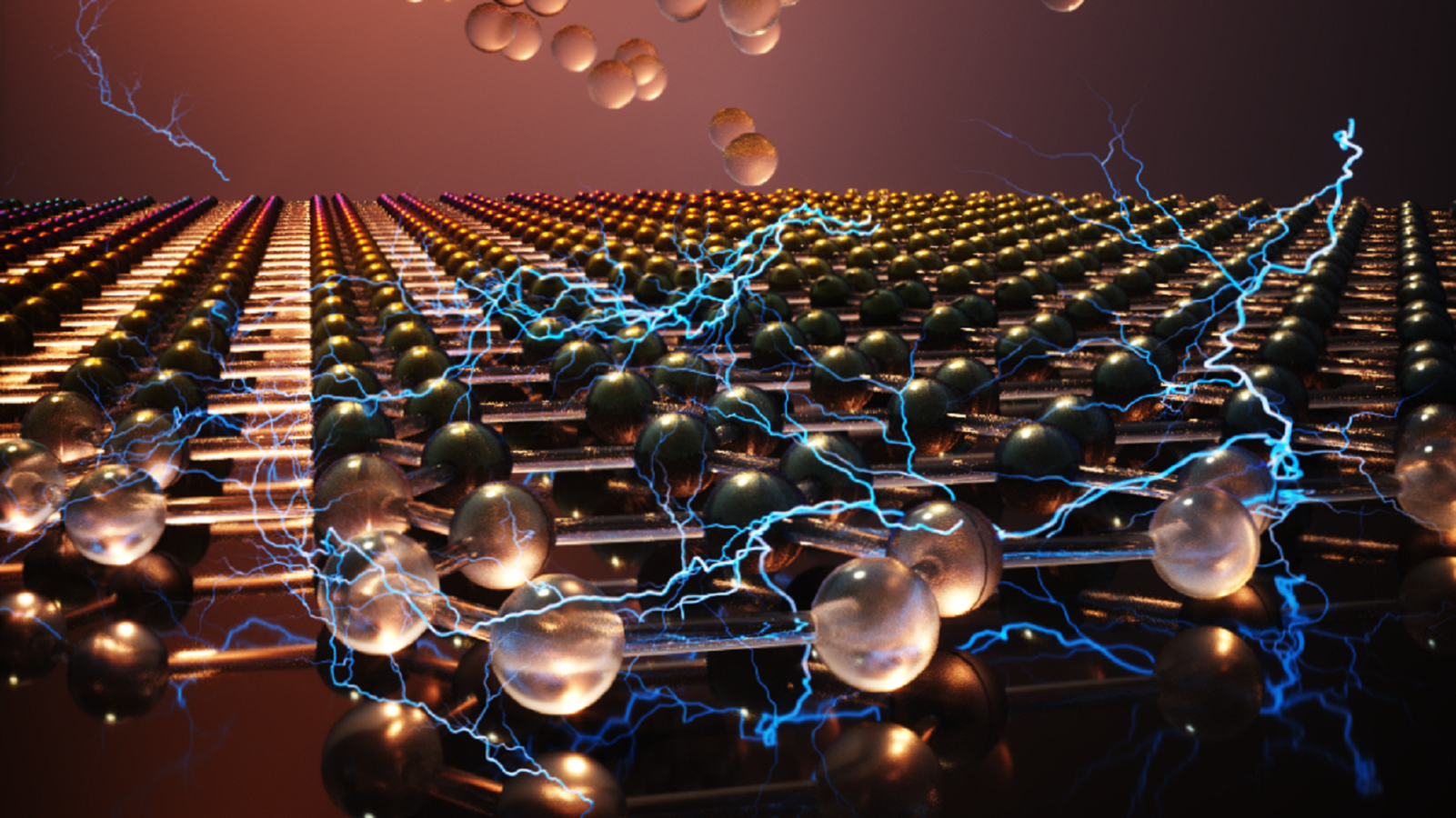

A team of researchers from the University of California at Berkeley and Argonne have pioneered a new type of ultrathin material that has special electronic properties, potentially making it useful for ultralow-power microelectronics.

This material falls into a class called ferroelectrics, which present a promising solution to help lower the power consumed by the ultrasmall electronic devices found in cell phones and computers. Ferroelectrics — the electrical analog to magnets — are a class of materials in which atoms are arranged off-center, leading to a spontaneous internal electric charge. This internal charge can reverse its direction when scientists expose the material to an external voltage.

Unfortunately, conventional ferroelectric materials, known as perovskites, lose their internal charge below around a few nanometers in thickness. This means they are not compatible with current-day silicon technology. This issue has previously prevented the integration of ferroelectrics into microelectronics.

In a study published in the journal Science, the research team discovered stable ferroelectricity in an ultrathin material just half a nanometer thick. That’s the size of a single atomic building block, about 200,000 times thinner than a human hair. The team grew this material directly on silicon. They found ferroelectricity emerges in zirconium dioxide — normally a nonferroelectric material — when it is squeezed to extremely thin scales, approximately 1-2 nanometers in thickness.

Caltech researchers decode complex cellular machinery

The nucleus of every cell in our bodies contains many complicated parts. One of the most intricate is called the nuclear pore complex, or NPC. Shaped like a donut with spider legs, the NPC serves as a gateway and guardian to the inner workings of the nucleus. It expands and contracts to allow beneficial things in, and keep harmful things out. Mutations in the NPC have been linked to many diseases, including Lou Gherig’s disease (known as ALS), and heart conditions, so understanding how it works may lead to better treatments.

A research team led by Caltech has spent nearly 20 years creating a full structural map of the NPC. Using the ultrabright X-rays of the APS, a DOE Office of Science user facility at Argonne — along with other similar facilities — researchers painstakingly determined the atomic structure of the NPC, protein by protein. This information greatly increases our knowledge and understanding of how the NPC works. The research was published in Science.

USC scientists use Argonne computing power, discover new application for ancient art

Scientists at the USC in Los Angeles used supercomputers and kirigami — the ancient Japanese art of paper cutting — at the Argonne Leadership Computing Facility (ALCF), a DOE Office of Science user facility located at Argonne, to make inroads in wearable electronics. By combining kirigami (which involves making exacting cuts to create intricate patterns) with autonomous reinforcement learning, the team is advancing the development of strong, stretchable materials for wearable electronics.

Knowing that a series of precise cuts would make a material strong and stretchable, the team created a two-dimensional length of molybdenum disulfide, a material that can be embedded with electronics. To arrive at the right kirigami pattern, the team used Argonne supercomputers to conduct thousands of simulations.

After the model learned kirigami design strategies, researchers used it to produce a combination of about one billion possible stretches and cuts. Using reinforcement learning (an artificial intelligence (AI) technique), the computer “taught” itself to produce a structure with optimal stretchability.

The ALCF is a DOE Office of Science user facility. USC’s work at the ALCF was funded by the National Science Foundation’s Future Manufacturing Program; the DOE Office of Science, Advanced Scientific Computing Research program; and the DOE Office of Science: Basic Energy Sciences and Advanced Scientific Computing Research program.

Oakland-based New Energy Nexus joins Argonne-led public-private alliance to build lithium battery supply chain

As widespread electrification drives demand for lithium-based batteries, the battery supply chain in the U.S. must expand. To achieve this goal, battery manufacturers must expand their output by 20 to 30 times and establish a secure and sustainable supply chain. Argonne announced the creation of Li-Bridge, a public-private alliance committed to building this supply chain.

In the first collaboration of its kind in the U.S. battery industry, New Energy Nexus in Oakland joined two other trade associations ― NAATBatt International and New York Battery and Energy Storage Technology Consortium, Albany ― to represent more than 600 industry stakeholders to improve the supply chain. Argonne serves as the facilitator between private industry and the Federal Consortium for Advanced Batteries, which recently released a “national blueprint” for lithium batteries to the year 2030. The plan puts the United States on a path to long-term competitiveness in the global battery value chain, outlining five critical goals for generating equitable, clean-energy jobs while mitigating climate change.

Argonne will work with DOE national laboratories across the country to meet national goals. The new alliance is seen as a major step forward in developing and sustaining the battery supply chain — critical to building electric vehicles and maintaining competitiveness worldwide.

Cerebras and Argonne collaboration leads to fastest AI system

The world’s fastest AI computer, Cerebras CS-1, is the result of a collaboration between Argonne and Cerebras Systems in Los Altos, which focuses on accelerating AI compute. Argonne was the first national laboratory to deploy the system in 2019 to solve deep learning computational and science problems. Deep learning, a subset of AI, allows computer networks to learn from large amounts of unstructured data.

The CS-1 integrates the Wafer Scale Engine, the fastest AI processor ever built, and enables AI practitioners to answer more questions and explore more ideas in less time. The CS-1 delivers record-breaking performance and scale to AI compute, and its deployment across national laboratories enables the largest supercomputer sites in the world to achieve a hundredfold to a thousandfold improvement over existing AI accelerators.

Argonne-led energy storage consortium technology leads to Sepion startup

Sepion Technologies in Emeryville was launched using technology developed at JCESR, one of DOE’s Energy Innovation Hubs. Led by Argonne, JCESR is a partnership of national laboratories, universities and industrial firms with more than 150 researchers. Its mission is to create materials that can be mixed and matched to build a diversity of next-generation batteries to transform transportation and the electric grid the way lithium-ion batteries transformed consumer electronics. JCESR developed a polymer membrane as a component of a novel design for the cells that make up a battery. That membrane gave birth to Sepion.

Since then, Sepion has been commercializing a membrane platform with a suite of products that enhance the performance and economics of lithium batteries and flow batteries. At the heart of the technology are membranes that can be dropped in with existing manufacturing processes to minimize barriers to market entry, the company website said.

Argonne teams with California firms on new drug for melanoma patients

Researchers from drug discovery company Plexxikon Inc. in Berkeley and biotechnology company Genentech in San Francisco collaborated with Argonne to develop Zelboraf®, which is sold in nearly 50 countries.

While using Argonne’s APS, a DOE Office of Science user facility, researchers determined the structure of a cancer‑causing mutated protein. They searched through hundreds of molecules to determine the structure of the one that could halt the cancer’s spread. The researchers wanted to develop a drug to prevent the enzyme from multiplying. The molecule the scientists selected to use in the drug functions like a lock-and-key mechanism, binding tightly to the mutated protein and blocking signals from it that tell cancer cells to multiply. The U.S. Food and Drug Administration approved Zelboraf® in 2011.