A new Argonne collaboration pairs electric scooters with parking to reduce traffic congestion across Illinois

Scientists from the U.S. Department of Energy’s (DOE) Argonne National Laboratory teamed up with the Civic Infrastructure Collaborative (CINCO) and Millennium Parking Garages in Chicago to test a new approach to transportation that combines off-street parking with electric scooter rentals. This approach can help reduce traffic congestion and greenhouse gas emissions in urban areas, where drivers often waste time and energy searching for on-street parking.

In August 2022, Argonne and CINCO began a pilot study with Millennium Garages, a massive underground parking facility in downtown Chicago. Customers signed up for a scooter rental in advance and had access to that scooter for the entire day. Over the two-year pilot program, the collaborative team found that parking customers were extremely interested in renting scooters to travel throughout the city, which helped alleviate traffic and carbon emissions.

The pilot program began with eight scooters as part of the Department of Energy’s SMART Mobility 2.0 program, an effort to improve transportation through testing affordable, safe and clean energy technologies. Now, Millennium Parking Garages is expanding its e-scooter fleet and taking on the associated operating and maintenance responsibilities. According to CINCO, this approach to transportation can be implemented in parking garages across Illinois and throughout the country.

Water-focused ‘innovation engine’ aims to drive economic development across Illinois, Ohio and Wisconsin

A new water-focused “innovation engine” aims to drive economic development and job creation in the Great Lakes region by finding new ways to recover clean water, energy and valuable materials from wastewater, while removing harmful chemicals. These efforts will be carried out by Great Lakes ReNEW, a collaboration of research institutions, universities, utilities, investors and development organizations spanning six states — including Illinois, Ohio and Wisconsin.

ReNEW is led by Current, a Chicago-based, water-focused innovation hub. Argonne and the University of Chicago are partners in the effort. The initiative will be funded by $160 million in potential grant money from the U.S. National Science Foundation. An initial $15 million portion of the grant will cover development activities in Illinois, Ohio and Wisconsin over the next two years. The remaining funds will be awarded contingent upon progress and could be applied more broadly across ReNEW member states.

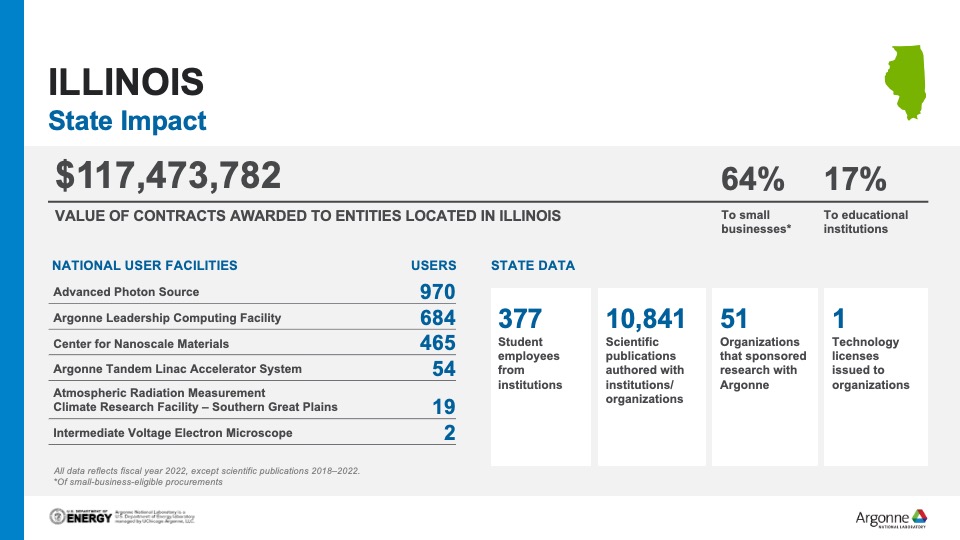

Argonne researchers model impact of roofing strategies in Chicagoland area

To help understand how climate is affecting urban communities, researchers at Argonne examined different types of roofing materials and their impact on near-surface temperature and cooling energy demand through regional modeling in the Chicago metropolitan area. The team ran a regional climate model combined with a multi-layer building system and three types of roofs: cool (painted a heat-reflecting white), green (vegetation) and solar panels.

They found that the three types of roofs reduced the near-surface temperature and air conditioning (AC) consumption demand during daytime hours when air temperature is the highest. Cool roofs reduced AC energy consumption the most, followed by green roofs and solar panel roofs.

Overall, the large-scale deployment of cool roofs has the best potential for cooling effects and cooling energy saving. They cost less than the other two technologies, and they do not require additional water. The results of the study can inform sustainable development approaches, lower summertime cooling energy demand and help minimize greenhouse gas emissions in the long term over the Chicago metropolitan area.

Students from across the Chicago region work closely with Argonne scientists to tackle future urban climate challenges

Over the summer of 2023, students from Chicago area universities assisted faculty and Argonne scientists with atmospheric instrumentation measurements and data collection as a part of the Urban Integrated Field Laboratory called Community Research on Climate and Urban Science (CROCUS) in the city of Chicago. CROCUS is a five-year, $25-million program funded by DOE’s Office of Science, Office of Biological and Environmental Research to understand how climate change will affect urban areas.

CROCUS involves seventeen partner organizations from across the Chicago metropolitan area and the country. Of those 17 partners, four of the academic partners are minority-serving institutions (MSI) helping educate and train the next generation of scientists to tackle future urban climate challenges. This includes Northeastern Illinois University (Northeastern), Chicago State University, City Colleges of Chicago and University of Illinois-Chicago.

MSIs are a critical group of CROCUS partners actively contributing to scientific research, bridging the research to urban communities surrounding their campuses, and helping address the underrepresentation of people of color in the scientific workforce. CROCUS is a meaningful collaboration between the university leaders, faculty and students at these institutions.

Argonne and Chicago State University install sensors to study urban climate change in Illinois

Scientists from Argonne and Chicago State University deployed a set of scientific instruments to better study the local impact of climate change.

It’s the second installation of scientific instruments for the Urban Integrated Field Laboratory called CROCUS in the city of Chicago. CROCUS is a five-year, $25 million program funded by DOE’s Office of Science, Office of Biological and Environmental Research to understand how climate change will affect urban areas.

The research will measure wind, temperature, rainfall, snow accumulation, radiation and air pollution. To collect this information, the team installed a Waggle node platform that integrates sensors and edge computing. This allows researchers to access environmental data in near-real time. In the next few years, CROCUS partners will deploy nearly 20 sensor arrays across the city to gather more data on Chicago’s changing climate.

Learn more about CROCUS at crocus-urban.org.

Argonne and Northeastern install sensors to study urban climate change in Illinois

Scientists from Argonne and Northeastern deployed a set of scientific instruments on the university’s rooftop to better study the local impact of climate change.

It’s the first installation of scientific instruments for the Urban Integrated Field Laboratory called CROCUS in the city of Chicago. CROCUS is a five-year, $25-million program funded by DOE’s Office of Science, Office of Biological and Environmental Research to understand how climate change will affect urban areas.

The research will measure wind, temperature, rainfall, snow accumulation, radiation and air pollution. To collect this information, the team installed a Waggle node platform that integrates sensors and edge computing. This allows researchers to access environmental data in near-real-time. In the next few years, CROCUS partners will deploy nearly 20 sensor arrays across the city to gather more data on Chicago’s changing climate.

Learn more about CROCUS at crocus-urban.org.

Argonne researchers share in Chicago Innovation Award for COVID wastewater testing

Argonne is among the winners of a 2022 Chicago Innovation Award for its work on a COVID wastewater surveillance system. In collaboration with the Discovery Partners Institute, Argonne researchers assembled one of the first teams in the nation to reliably analyze samples of raw sewage for evidence of SARS-CoV-2 RNA in 2021, providing real-time information to help both the Chicago Department of Public Health and the Illinois Department of Public Health through the pandemic.

Monitoring wastewater for infectious diseases will continue to be an essential tool for public health, not just during the ongoing COVID pandemic, but also as communities prepare for possible outbreaks of everything from flu and RSV to polio and mpox to other emerging diseases. Argonne’s expertise in genetic sequencing gives Illinois health officials and healthcare providers vital insights into understand what vaccines, medicines and supplies they need to treat people and what precautions they should take to keep people safe.

Argonne model informs the technology of the winner of a prestigious battery recycling prize

Argonne has a model which informed the technology of Schaumburg, Illinois-based Renewance. The company subsequently led a winning team in a prestigious battery recycling prize competition. This successful application of the model, called EverBatt, demonstrates its potential to help shape a robust battery recycling industry.

EverBatt is a free, publicly available Excel-based tool. It enables users to directly compare the costs and environmental impacts of battery recycling and other battery supply chain processes. It is designed to inform investment decisions in sustainable, cost-effective recycling infrastructure.

Renewance’s digital platform helps owners of end-of-life grid batteries determine the most cost-effective, environmentally friendly reuse, repurposing and recycling options.

Many of Renewance’s customers need to decommission remote battery sites. This involves dismantling the components before transporting them to a recycling facility. Renewance can potentially hold the equipment in “interim storage” warehouses until there is enough volume for transport by full truck loads.

Argonne customized EverBatt for Renewance. A key insight from the model was that costs and greenhouse gas emissions from interim storage would usually be more than offset by the benefits of full truck shipments. This helped Renewance demonstrate the benefits of interim storage to its customers.

New Argonne collaboration to advance urban science in the Chicagoland region

Argonne and partners will establish an Urban Integrated Field Laboratory called CROCUS focusing on the Chicago region.

CROCUS will advance urban climate science by studying climate change effects at local and regional scale. Focusing on community input, CROCUS will identify questions and specific areas of urban climate change to study, ensuring that research results directly benefit local residents.

Partnering with local and regional colleges and universities, Argonne will provide educational and workforce development opportunities to students from minority-serving institutions and historically Black colleges and universities. These include University of Illinois Chicago, Northeastern, City Colleges of Chicago, Chicago State University, Northwestern University, University of Chicago and University of Illinois Urbana-Champaign.

The CROCUS research team will also partner with community-based organizations on Chicago’s South and West Sides to envision and create a just transition with clean energy and green infrastructure that meets each community’s needs. Community partners include Blacks in Green, Greater Chatham Initiative, Puerto Rican Agenda and Metropolitan Mayors Caucus.

Go to the CROCUS website.

Startup that participated in Argonne’s Chain Reaction Innovations program works toward cleaner fuel, lower emissions with help from John Deere

Machinery manufacturer John Deere — Iowa’s largest manufacturing employer — has made an equity investment in Geneva, Illinois–based ClearFlame Engine Technologies, helping to support an engine testing and pilot demonstration program. ClearFlame’s engine technology enables diesel engines to operate on plant-based ethanol, lowering emissions without compromising overall performance.

ClearFlame co-founders Julie Blumreiter and B.J. Johnson are alumni of the first class of Chain Reactions Innovations, a Lab-Embedded Entrepreneurship Program at Argonne. Working with Argonne researchers at the Lab’s Advanced Powertrain Research Center, Blumreiter and Johnson were able to advance their technology through additional engineering and data collection. Since then, ClearFlame has raised more than $20 million to continue commercializing its technology, and now has its first pilot trucks on the road.

Currently, ClearFlame is testing its technology on a nine-liter John Deere engine commonly used in a range of off-road equipment. Using corn-based ethanol in place of diesel can reduce carbon dioxide emissions by 45%-50%, with other feedstocks offering even larger reductions as the ethanol fuel pool is on track to reach net-zero for greenhouse gases by 2035.

UChicago/Carnegie scientists use Argonne’s Advanced Photon Source to find ‘superionic ice’ that could exist inside other planets

For generations, science students were taught that water takes three forms: solid, liquid or gas. But now scientists have discovered a new phase: superionic ice. This type of ice forms at extremely high temperatures and pressures, like those found at the center of planets. Because scientists cannot explore those places physically, they attempt to replicate the conditions in the laboratory, squeezing samples between diamond “anvils” and heating them with high-powered lasers.

A team of researchers from the University of Chicago and the Carnegie Institution for Science, Washington D.C., used the extremely bright X-ray beams of the Advanced Photon Source (APS) a DOE user facility at Argonne, to reliably create, sustain and examine superionic ice.

Scientists are still exploring the full range of the properties of superionic ice. However, being able to map where the ice occurs, promises to reveal more about planet formation and even where to look for life on other planets. From this discovery, scientists believe these conditions exist deep inside Neptune and Uranus and in other icy, rocky planets like them in the universe.

The APS is a DOE Office of Science user facility.

UChicago investigates origin of living cells

One of the most important questions in science is how life began on Earth. A possible theory is that wet-dry cycling created conditions that allowed membraneless compartments called coacervates to act as homes for chemicals to combine into life-sustaining molecules. Scientists from UChicago and Pennsylvania State University collaborated to study coacervates in water with makeup similar to that of pond water. A pond would regularly dry up and be replenished with rain or changing tides. This cycle of dehydration and rehydration could provide an environment where molecular building blocks could assemble into the molecules of life: proteins, DNA and RNA.

The team used the extremely bright X-rays at the APS to study coacervates as they underwent phase changes. Small-angle X-ray scattering at the APS suggested how the structures may have behaved in early Earth during a wet-dry cycle. The team found that repetitive cycles of hydration and dehydration caused the compartments to undergo changes in their composition and structure. Their discovery could signal important implications for the design of electronics and drug delivery systems.

IIT studies tarantula muscles with the APS to learn about human heart

Connected to a network of veins, arteries and capillaries spanning more than 60,000 miles, the heart is the human body’s most important muscle. Yet, even with heart disease ranking as the world’s number one cause of death, understanding the heart’s physiology remains elusive. To learn more about muscle function, researchers used the BioCAT beamline at Argonne’s APS to study how tarantula muscles contract and relax. Both human and spider muscles contain myosin, a family of motor proteins essential to movement, and studying the myosin in spider muscles may provide insights into the ways our own muscles move.

Scientists at the Illinois Institute of Technology in Chicago and the University of Massachusetts Medical School in Worcester conducted X-ray diffraction experiments to learn how tarantula muscles are activated. Tarantulas have well-ordered filaments in their muscles, which allows for strong X-ray diffraction patterns. The team demonstrated the presence of two interacting molecular motors in live muscle that produce the force in that muscle — structures that, other studies suggest, also exist in the human heart. The team’s findings may help advance the design of more-effective drugs for human heart conditions, such as hypertrophic cardiomyopathy, in which a thickened heart muscle can lead to cardiac arrest.

The APS is a DOE Office of Science User Facility.

Advanced Diamond Technologies built with Argonne technology

Romeoville, Illinois-based Advanced Diamond Technologies (ADT) leveraged the pioneering technology discovered by Argonne to produce diamond films for industrial, electronic, mechanical and medical applications. The start-up was co-founded in 2003 by Argonne Materials Science researchers Orlando Auciello, John Carlisle and Neil Kane. While Carlisle was an executive with ADT for a while, he later returned to Argonne to encourage the next generation of innovators as director of Chain Reaction Innovations, which gives science entrepreneurs access to Argonne’s broad, multi-discipline resources for two years to help mature their technologies.

The pivotal research behind ADT started at Argonne’s Chemistry division (now Chemical Sciences and Engineering) and was supported by DOE’s Basic Energy Sciences program within DOE’s Office of Science. ADT’s products became so successful that by 2019, Chicago-based John Crane, a provider of engineered products, acquired ADT’s industrial division.

Caterpillar finds answers for better engines at Argonne

Caterpillar Inc., Deerfield, Illinois collaborated with Argonne and software developer Convergent Science Inc. in Madison, Wisconsin to modernize its engine development process. Caterpillar, a manufacturer of construction and mining equipment, relied on Argonne’s world-class resources to help improve the fuel economy, reliability and longevity of its engines. If it wasn’t for leveraging Argonne’s resources, Caterpillar would have faced a costly and time-intensive process.

Argonne’s pioneering leadership in developing engine models and software for computer simulations provided the necessary virtual look that Caterpillar needed before production even started. It also provided a better understanding of how engine parameters interact. This collaboration allowed Caterpillar to significantly reduce the number of its experimental test campaigns, shrink the engine development timescales and lower the cost of its engine development process.